Type 1 cement is commonly referred to as Portland cement in the construction industry and manufacturing plants. This type of cement is widely used in concrete making. Thus, the role of cement in concrete making is to stick the gravel in the concrete. Type 1 cement or Portland cement is mostly used in areas that are dry and temperate. Of course, it should be noted that this cement can be used only in concretes that sulfates can not be in the vicinity of concrete…

It can be used in all reinforced and unreinforced concrete structures and basically all cases that do not require special properties such as resistance to aggressive ions and low hydration heat. Due to the high initial and final strength, it is used especially in cases where the need to open and move the concrete molding faster, for example, is used in the construction of concrete silos. Also, due to the high amount of C3S phase and as a result of the heat produced, this cement can be used in moderate winter weather, and for this reason, the use of this type of cement in tropical regions where there is a risk of increasing the concrete temperature should be done with caution.

Other features of this product include the reduction of cement consumption to achieve constant concrete strength, the durability of concrete made with it compared to 325-1 cement, the ability to mold earlier than 325-1 cement, and the increase in the speed of construction. He pointed out that due to the high initial resistance of concrete and the increase in the durability of concrete due to the gradual and continuous increase in resistance and the high final strength. The application of this product is mostly in general uses and normal weather conditions and where there is no problem of sulfate and chlorine and there is a need for quick concrete setting, for example in the construction of sidewalks and road paving and mortar for masonry buildings and structures that have high resistance. They need such as: foundations, columns, bridges and tunnels are recommended.

Note: This type of cement is not allowed to be used in sulfated and chlorinated environments.

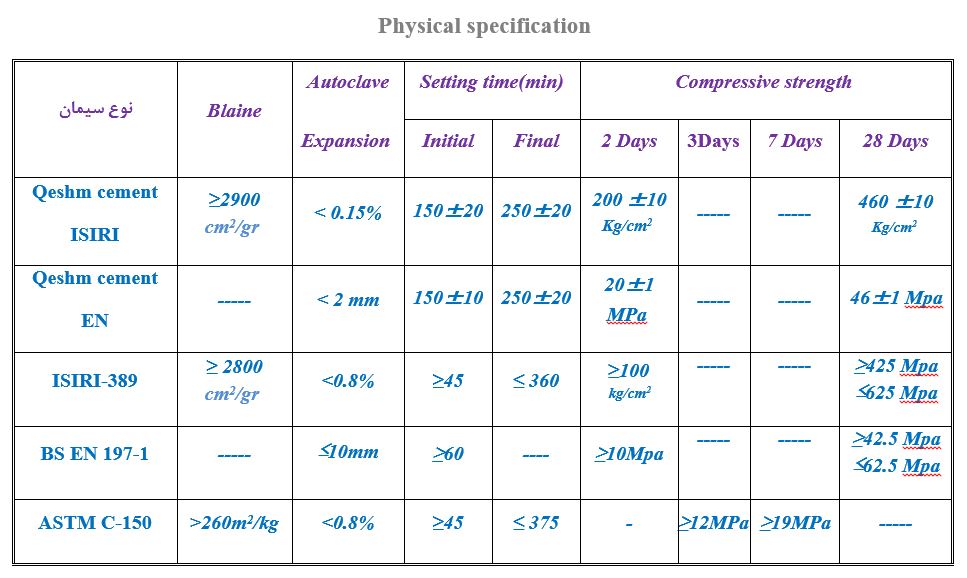

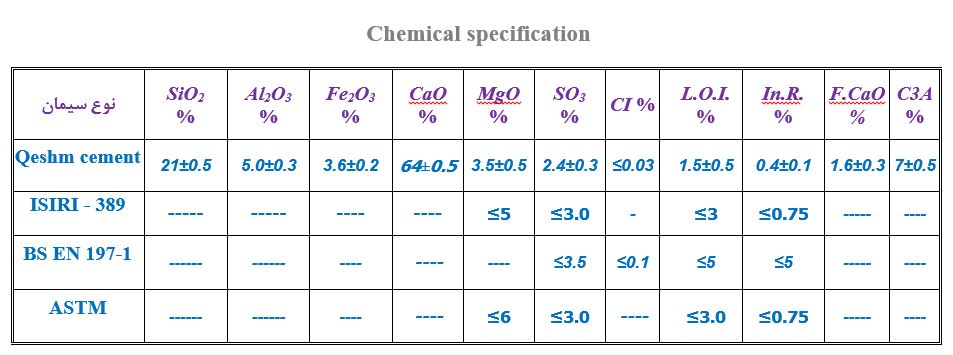

This cement is in the middle of resistance type of type one cement, which has higher resistance than type 2 and 1-325 by maintaining the chemical properties of type 2 cement, and its mortar or concrete has medium strength in sulfate environments. Physical and chemical properties of type 1-425 cement (I-42.5) according to the national standard of Iran and the EN standard of this company are as follows.

Other features of this product can be reduced cement consumption to achieve a stable strength of concrete, more durable concrete made with it than cement 1-325, the ability to mold earlier than cement 1-325, increase the speed of operation in construction Due to the high initial strength of concrete and increase the durability of concrete due to the gradual and continuous increase in strength and high final strength. This product is mostly used in general uses and normal weather conditions and where there is no problem of sulfate and chlorine and the need for fast setting of concrete, for example in the construction of sidewalks and paving roads and mortar of buildings and structures that have high strength Required such as: foundations, columns, bridges and tunnels are recommended.

Note: Consumption of this type of cement is not allowed in sulfated and chlorinated environments.